From the north of the Bourgogne region to the south, depending on the characteristics of the vintage, vinification of red wines can vary greatly. For example, some winegrowers destalk their grapes, while others vinify in whole bunches. The varietal plays a key role, too. Pinot Noir, which is particularly delicate, requires a more careful approach than any other grape.

Vinification of red wine starts with alcoholic fermentation, a process during which the grape juice turns into wine. Unlike with white wines which are pressed on arrival in the winery, grapes for red wines, either crushed or in whole bunches, are placed in vats to macerate. The juice is clear to start with and requires contact with the skins and pips to bring color and tannins to the wine. During this maceration process, the alcoholic fermentation begins, either naturally or sometimes triggered with the addition of yeasts.

Each day, the cap of skin and pips is broken up and pushed down into the juice to help the development of color and tannins. The process is known as pigeage and used to be done with the feet. Nowadays, a special tool is used to protect the raw material.

When fermentation is complete, the wine is pressed and then placed in vats or barrels for ageing.

During the ageing process, the red wines undergo a second malolactic fermentation, during which the malic acid in the wine turns to lactic acid, making the wines smoother.

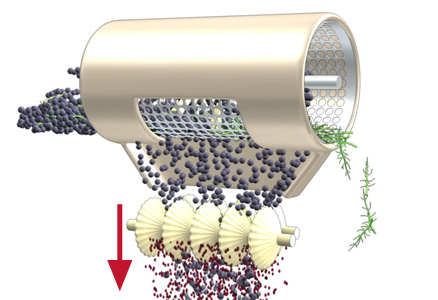

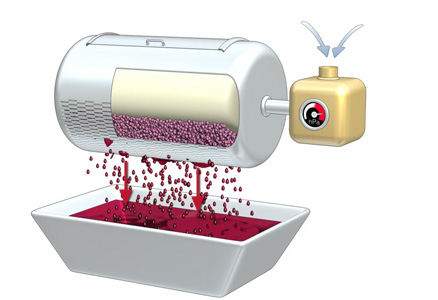

Removing grapes berries from the stems (optional). Grape crushing and release of the juice.

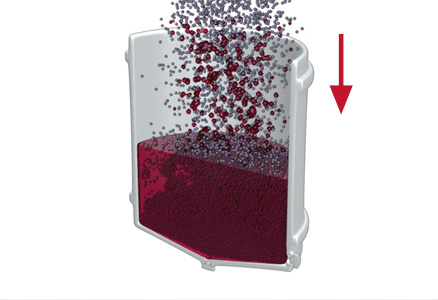

Vatting the juice and the solids (skin, seeds) for the maceration process.

The “cap” (consisting of solids) is punched down into the must (juice). The must is pumped over to the top of the tank, wetting the “cap.”

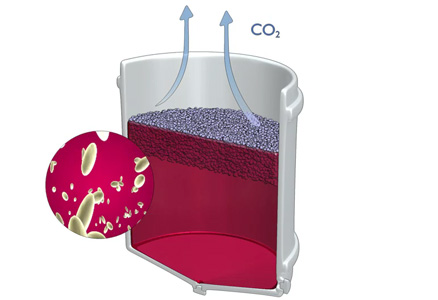

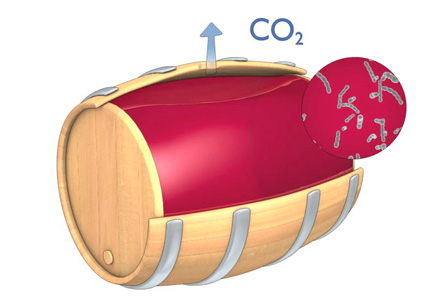

Transformation of sugars from the must into alcohol, and aroma release by yeast fermentation (Saccharomyces cerevisiae).

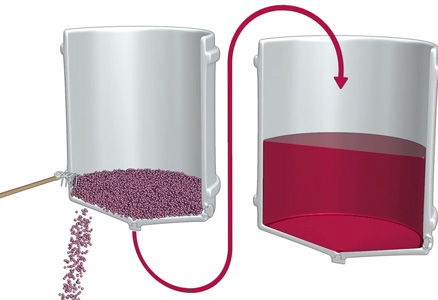

The wine is devatted (free run juice) and transferred to tanks or barrels by gravity. The pomace is collected for pressing.

An inflated bladder presses the pomace and the juice still present is recovered: resulting in press wine.

Traditionally, free-run juice and press wine are assembled before maturing. The wine is cloudy. The heaviest particles deposit at the bottom of the tank. The “clear” wine is placed in barrels and the must deposit is removed.

Microorganisms (lactic acid bacteria) transform malic acid into lactic acid.

Optional step.

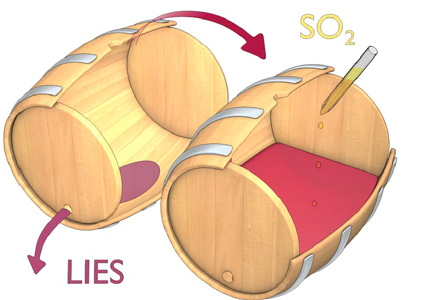

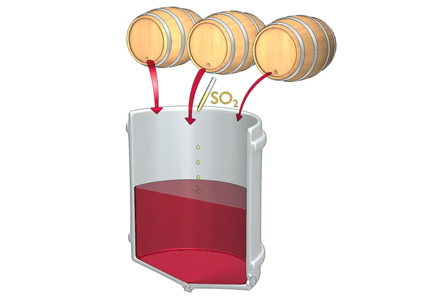

The “clear” wine is racked, i.e. moved from one container to another (tank or barrel), the lees (deposit at the bottom of the tank or barrel) are removed.

The wine remains fragile, sulphur is added to protect it.

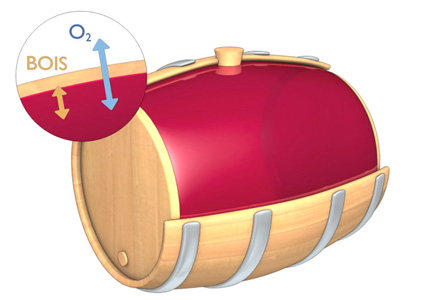

The wine is kept in casks (228 litres barrels) for several months. Exchanges with and through the wood take place.

The wine is racked into a tank and its sulphur level is adjusted if necessary.

Wine produced from the same plot or several plots in the same appellation, is blended.

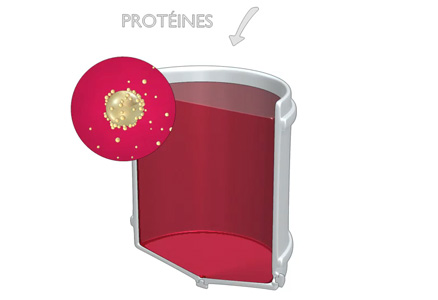

Add if necessary protein (such as egg whites), mineral, or synthetic fining agents which draw down suspended particles towards the bottom of the tank.

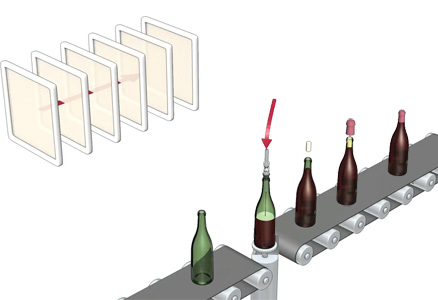

Wine is sometimes filtered to make it limpid and bright. It is then transferred into a tank to be bottled using a bottling machine and corked with a corking machine.