Almost all Bourgogne varietals are authorized to make Crémant de Bourgogne (Pinot Noir, Chardonnay, Gamay, Aligoté, Melon, Sacy, etc.), but there is nothing left to chance when it comes to plot selection.

The grapes are carefully chosen and the production process differs to that of still wines. The grapes are harvested early to preserve the acidity required to give Crémant de Bourgogne wines all their freshness.

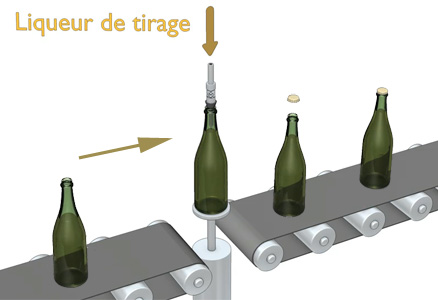

The sparkle is created by the addition of a liqueur de tirage (base wine mixed with sugar and yeast) when the wine is bottled. This causes a second fermentation to take place in the bottle, which creates carbon dioxide. This in turn produces the bubbles in the glass when the wine is poured.

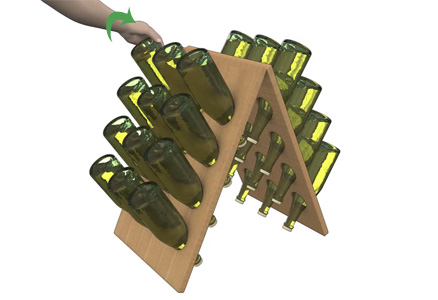

The bottles are then held in racks pointing downwards so the yeast deposits collect in the neck. The bottles are then rotated or “riddled”, by hand or by machine, to encourage the deposits to fall.

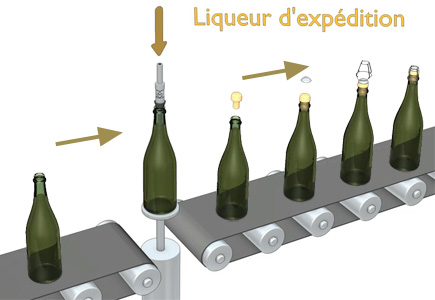

These yeasts are then disgorged and a liqueur d’expédition is added which determines the sweetness of the finished wine, and whether it will be brut, sec, demi-sec or doux.

You can find out about each step in the process by watching our animation about the production of Crémant de Bourgogne wines.

An inflated bladder presses the white or red grape harvest (whole bunches) and the juice is

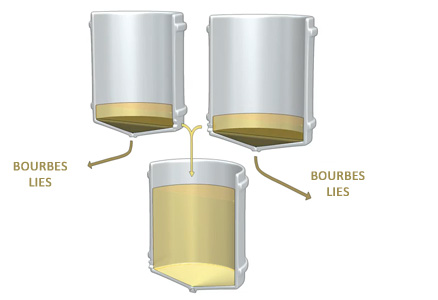

collected in a tank. The press juice is fractioned based on the quality of juices produced, which will be processed separately.

The juice is cloudy. The heaviest parts settle to the bottom: this is the must deposit. This natural phenomenon may be accelerated (eg. cooling). The “clear” juice is put into a tank or a barrel, and the must deposit is removed.

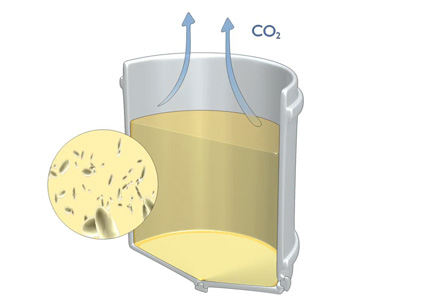

Transformation of sugars from the must into alcohol, and aroma release by yeast fermentation (Saccharomyces cerevisiae). The wine is racked, i.e. moved from one container to another.

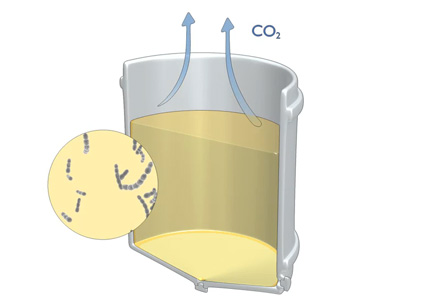

Microorganisms (lactic acid bacteria) transform malic acid into lactic acid (non systematic step).

Crucial step performed in the winter following the harvest consisting of harmoniously blending various wine lots from different terroirs and grapes varieties.

The tirage liqueur (sugars and yeast) is added to the base wine in bottles which are then closed with a crown cap.

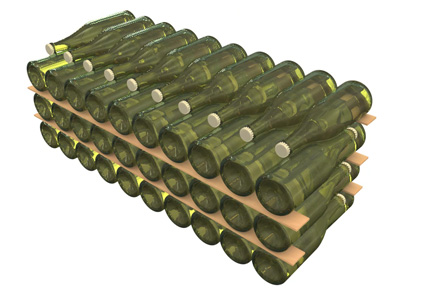

The wine ferments again in the bottle due to the added sugar and yeast (inner bottle pressure rises). Bottles are then stored horizontally on laths for a minimum of 9 months for maturing + 3 months before being introduced to the market.

The bottles are placed top-down in special racks (or automatic riddling machines) and periodically turned and slightly shaked: a ¼ turn 3 times, then a 1/8 turn in the opposite direction.

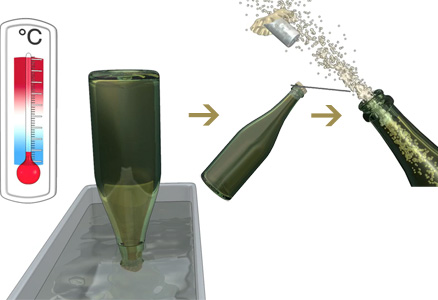

The bottle-neck is immersed into an ice-cold solution. The deposit forms an ice plug which is propelled out of the bottle by the inner pressure inside of it.

The expedition liqueur, whose composition is the secret of each winemaker, is added to the wine, as well as sulfites (to protect the wine). The bottles are corked with a specific cork covered with a wire- cap.